What are 3 types of chemical hazards

In the realm of workplace safety, chemical hazards pose a significant threat to the health and well-being of individuals. These hazards can manifest in various forms, each with its distinct characteristics and potential risks. This article aims to shed light on the three primary types of chemical hazards, providing a comprehensive understanding of their nature, sources, and consequences.

What are 3 Types of Chemical Hazards?

Chemical hazards encompass a wide range of substances that can pose risks to human health and the environment. While countless chemicals exist, they can be broadly categorized for understanding their potential dangers. Three major types of chemical hazards are corrosives, flammables, and toxins. Each presents unique challenges and requires different safety protocols for handling and storage.

Corrosives: Substances that Destroy Living Tissue

Corrosive chemicals are substances that cause visible destruction or irreversible alterations to living tissue by chemical action at the site of contact. This destruction can range from mild irritation to severe burns, depending on the concentration and duration of exposure. The damage occurs through chemical reactions that break down the proteins and other molecules in living cells. Examples include strong acids (like sulfuric acid) and strong bases (like sodium hydroxide). Contact with corrosives can lead to immediate pain, blistering, and scarring. Protective equipment like gloves, eye protection, and specialized clothing are crucial when handling corrosive materials. Proper ventilation is also vital to avoid inhalation of corrosive fumes.

| Characteristic | Description |

|---|---|

| Chemical Action | Direct chemical attack on living tissue. |

| Effects | Burns, blisters, tissue damage, scarring. |

| Examples | Sulfuric acid, Sodium hydroxide, Hydrochloric acid. |

| Safety Precautions | Protective clothing, eye protection, proper ventilation, immediate first aid. |

Flammables: Substances that Readily Ignite and Burn

Flammable chemicals are substances that can easily catch fire and burn rapidly. These substances have low ignition temperatures and readily react with oxygen, releasing significant amounts of heat and often producing toxic byproducts. Flammability is influenced by factors like the substance's vapor pressure, flash point, and the presence of an ignition source. Proper storage in designated areas away from ignition sources is essential to prevent fires. Flammable materials should be handled with care, and appropriate fire suppression systems (e.g., fire extinguishers) must be readily available. Examples include gasoline, ethanol, and acetone. Spills must be cleaned up immediately to avoid fire hazards.

| Characteristic | Description |

|---|---|

| Ignition Temperature | Low temperature at which a substance will ignite. |

| Vapor Pressure | The pressure exerted by the vapor above a liquid. High vapor pressure increases flammability. |

| Examples | Gasoline, Ethanol, Acetone, Methane. |

| Safety Precautions | Proper storage, no ignition sources nearby, appropriate fire suppression systems. |

Toxins: Substances that are Poisonous or Harmful

Toxic chemicals are substances that can cause adverse health effects when ingested, inhaled, or absorbed through the skin. Toxicity varies greatly depending on the chemical, the dose, and the route of exposure. Some toxins cause acute effects (immediate and severe reactions), while others cause chronic effects (long-term health problems, such as cancer or organ damage). Exposure limits are often established to minimize risks. Examples include lead, mercury, and various pesticides. Personal protective equipment (PPE) and proper ventilation are vital to prevent exposure. Handling toxic substances requires specific training and adherence to established safety procedures.

| Characteristic | Description |

|---|---|

| Route of Exposure | Ingestion, inhalation, skin absorption. |

| Effects | Acute or chronic health problems, organ damage, cancer. |

| Examples | Lead, Mercury, Cyanide, Pesticides. |

| Safety Precautions | PPE, proper ventilation, strict handling procedures, waste disposal protocols. |

Oxidizers: Substances that readily give off oxygen or other oxidizing substances and may cause or enhance combustion of other materials.

Oxidizers are chemical compounds that readily yield oxygen or other oxidizing substances. They increase the flammability of other materials and may spontaneously ignite them. Examples include hydrogen peroxide and many nitrates. Safe storage separate from flammables is essential to prevent fires or explosions. Contact with skin or eyes should be avoided, and appropriate PPE is required.

Reactive Substances: Substances that are readily undergo violent chemical change without external stimulus.

Reactive substances are chemicals prone to unpredictable chemical reactions, often violently, with other materials or under certain conditions (e.g., heat, moisture, shock). They might explode, generate toxic gases, or cause other hazards. These chemicals require specialized handling and storage, often in inert atmospheres or isolated environments. Examples include alkali metals and some organic peroxides.

What are the three 3 types of hazards?

What are the three types of hazards?

While hazard categorization can vary depending on the context (e.g., workplace safety, environmental risk assessment), a common and widely accepted framework divides hazards into three primary types: physical, chemical, and biological. These categories encompass a broad range of potential dangers and provide a useful structure for risk management and control.

Physical Hazards

Physical hazards are dangers that arise from physical sources and can cause injury or harm through contact, exposure, or proximity. These hazards are often immediately apparent and can range from relatively minor inconveniences to catastrophic events. Effective risk control often involves engineering controls, administrative controls, and the use of personal protective equipment (PPE).

- Mechanical hazards: These include moving machinery, sharp objects, electricity, and ergonomic stressors that can cause musculoskeletal injuries.

- Environmental hazards: This category encompasses things like extreme temperatures (heat or cold), noise, radiation (ionizing and non-ionizing), vibration, and lighting issues.

- Falls and trips: These are common physical hazards leading to injuries, often caused by uneven surfaces, obstacles, inadequate lighting, or slippery floors.

Chemical Hazards

Chemical hazards refer to dangers posed by exposure to chemicals in various forms, including solids, liquids, and gases. These hazards can cause a wide range of adverse health effects, from mild irritation to severe illness or death, depending on the specific chemical, the route of exposure, and the level of exposure. Managing chemical hazards requires careful handling, storage, and the use of appropriate PPE and engineering controls.

- Toxic substances: These chemicals can cause poisoning and damage to organs upon ingestion, inhalation or skin contact. Examples include heavy metals and certain pesticides.

- Corrosive materials: These chemicals can cause damage to skin, eyes, and other tissues through direct contact. Examples include strong acids and bases.

- Flammable substances: These chemicals are easily ignited and can cause fires or explosions. Examples include gasoline, propane, and ether.

Biological Hazards

Biological hazards are dangers originating from living organisms or their products. These hazards can include bacteria, viruses, fungi, parasites, and other biological agents that can cause infections or diseases. Controlling biological hazards often involves hygiene practices, sterilization techniques, and the use of appropriate PPE, such as gloves and masks.

- Infectious agents: Bacteria, viruses, and fungi that cause diseases like influenza, tuberculosis, and various fungal infections.

- Allergens: Substances like pollen, dust mites, and animal dander that can trigger allergic reactions in susceptible individuals.

- Toxins: Poisons produced by living organisms, such as snake venom or certain types of mold toxins.

Ergonomic Hazards

Ergonomic hazards relate to the design of the workplace and the tasks performed, which may lead to musculoskeletal disorders (MSDs) and other injuries over time. These hazards are often overlooked but can have significant long-term health consequences. Mitigation strategies focus on adjusting workstations, using appropriate tools, and implementing proper lifting techniques.

- Repetitive movements: Performing the same motions repeatedly can lead to strain and injury.

- Awkward postures: Maintaining uncomfortable positions for extended periods can cause muscle fatigue and pain.

- Forceful exertions: Lifting, pushing, or pulling heavy objects can strain muscles and joints.

Psychosocial Hazards

Psychosocial hazards stem from workplace factors that affect mental health and well-being. They can lead to stress, burnout, anxiety, and depression, impacting both individual health and workplace productivity. Addressing these hazards requires a proactive approach, focusing on creating a positive and supportive work environment.

- Workplace stress: High workload, tight deadlines, and lack of control can contribute to stress.

- Violence and aggression: Bullying, harassment, and physical threats can create a hostile work environment.

- Lack of support and recognition: Poor communication, inadequate training, and insufficient recognition can negatively affect morale and mental well-being.

What are 3 common hazards?

Three common hazards are slips, trips, and falls; fire hazards; and exposure to hazardous chemicals. These hazards are prevalent in various settings, from homes and workplaces to public spaces. Their impact ranges from minor injuries to severe consequences, even fatalities. Understanding these hazards and implementing appropriate preventative measures is crucial for ensuring safety.

Slips, Trips, and Falls

Slips, trips, and falls are among the most frequent workplace accidents, often resulting in sprains, fractures, and head injuries. These incidents are frequently caused by cluttered walkways, uneven surfaces, and inadequate lighting. Implementing preventative measures is key to reducing the risk.

- Maintain clean and clutter-free walkways: Regularly remove obstacles and spills.

- Ensure adequate lighting: Well-lit areas improve visibility and reduce the risk of tripping.

- Use appropriate footwear: Wear shoes with good traction to minimize slips.

Fire Hazards

Fire hazards encompass a wide range of risks, from small kitchen fires to large-scale industrial blazes. The severity of a fire hazard depends on factors such as the presence of flammable materials, the proximity to ignition sources, and the availability of effective fire suppression systems. The consequences can be devastating, leading to property damage, injuries, and even fatalities.

- Regular fire safety inspections: Identify and address potential fire hazards promptly.

- Proper storage of flammable materials: Keep flammables away from ignition sources and in designated areas.

- Employee training on fire safety procedures: Ensure everyone knows how to react in case of a fire.

Exposure to Hazardous Chemicals

Many workplaces utilize chemicals that pose significant health risks if handled improperly. Exposure to hazardous chemicals can lead to a wide range of health problems, from minor skin irritation to severe respiratory illnesses, even cancer. Safe handling and storage are paramount.

- Proper labeling and storage: Chemicals should be clearly labeled and stored according to safety guidelines.

- Use of appropriate personal protective equipment (PPE): Gloves, respirators, and eye protection should be worn when handling hazardous chemicals.

- Regular safety training: Employees must understand the risks associated with specific chemicals and proper handling procedures.

Electrical Hazards

Electrical hazards are a significant concern in many environments. Faulty wiring, damaged equipment, and improper use of electrical appliances can lead to electric shocks, fires, and even fatalities. Implementing proper safety measures is critical to prevent electrical hazards.

- Regular inspection and maintenance of electrical equipment: Identify and repair faulty wiring or damaged equipment.

- Use of Ground Fault Circuit Interrupters (GFCIs): These devices protect against electric shocks in wet areas.

- Proper use of electrical appliances: Avoid overloading circuits and using damaged equipment.

Biological Hazards

Biological hazards encompass risks from various biological agents such as bacteria, viruses, fungi, and parasites. Exposure can occur through various routes including inhalation, ingestion, or direct contact. These hazards are common in healthcare settings, research labs, and certain industries. Understanding and implementing appropriate control measures is essential to minimize risks.

- Proper hygiene practices: Handwashing, disinfection, and proper waste disposal are crucial.

- Use of appropriate personal protective equipment (PPE): Gloves, masks, and eye protection should be used when handling potentially infectious materials.

- Vaccination and preventative measures: Vaccines and other preventative measures can help protect against infectious diseases.

What are the 3 main hazard classification categories?

The three main hazard classification categories are generally physical hazards, chemical hazards, and biological hazards. While specific classifications and sub-categories can vary depending on the regulatory body or industry, these three overarching categories encompass a vast majority of workplace and environmental hazards.

Physical Hazards

Physical hazards are dangers that arise from sources that have the potential to cause harm through physical means. These hazards don't involve chemical reactions or biological agents. Instead, they present a direct threat through factors like energy, motion, or environmental conditions. Understanding and mitigating physical hazards often involves implementing engineering controls and safety procedures to minimize risks.

- Mechanical hazards: These include moving machinery, rotating parts, pinch points, sharp edges, and falling objects.

- Ergonomic hazards: These relate to the design and arrangement of the workplace, leading to strains, sprains, repetitive stress injuries, and other musculoskeletal disorders.

- Environmental hazards: These encompass extremes of temperature, noise, vibration, radiation, and insufficient lighting.

Chemical Hazards

Chemical hazards encompass risks associated with exposure to substances that can cause harm through chemical reactions or interactions within the body. These hazards can manifest in various forms, ranging from acute poisoning to long-term health effects, and understanding their properties is crucial for effective risk management. Appropriate handling, storage, and personal protective equipment (PPE) are critical in mitigating these risks.

- Toxic chemicals: Substances that can cause poisoning or other harmful effects even in small amounts. Examples include lead, mercury, and cyanide.

- Corrosive chemicals: Substances that can destroy living tissues through chemical reactions. Examples include acids and alkalis.

- Flammable and explosive chemicals: Substances that can easily ignite or explode, posing significant fire and explosion risks.

Biological Hazards

Biological hazards refer to risks stemming from exposure to living organisms or their products that can cause illness or injury. These hazards can include bacteria, viruses, fungi, parasites, and their toxins. Effective control measures often involve hygiene practices, sanitation, vaccination, and engineering controls to limit exposure. Proper identification and handling of biological materials are essential to minimize risks.

- Infectious agents: Bacteria, viruses, fungi, and parasites that can cause diseases like influenza, tuberculosis, and HIV.

- Biotoxins: Toxins produced by living organisms, such as venom from snakes or toxins from poisonous plants.

- Allergens: Substances derived from living organisms that can trigger allergic reactions in susceptible individuals. Examples include pollen, mold spores, and animal dander.

Psychosocial Hazards

While not always explicitly included in the main three, psychosocial hazards are increasingly recognized as significant workplace risks. These hazards relate to factors within the work environment that can negatively impact mental and emotional well-being. Addressing these hazards requires a proactive approach focused on creating a supportive and healthy work environment.

- Stress: Excessive pressure, workload, or demands that can lead to burnout and mental health issues.

- Violence: Threats of or actual physical assaults, harassment, or intimidation in the workplace.

- Bullying and harassment: Unacceptable behavior that creates a hostile or offensive work environment.

Ergonomic Hazards (Detailed)

Ergonomic hazards encompass a wide range of factors related to the physical setup and demands of the workplace, leading to musculoskeletal disorders (MSDs). Addressing these hazards often involves improving the design of workstations, tools, and tasks to reduce strain and promote proper body mechanics. This proactive approach is essential for preventing injuries and maintaining employee well-being.

- Awkward postures: Sustained postures that place stress on muscles and joints, such as prolonged bending, twisting, or reaching.

- Repetitive movements: Repeated actions that can lead to overuse injuries, such as carpal tunnel syndrome or tendinitis.

- Forceful exertions: Using excessive force to lift, carry, or manipulate objects, potentially leading to back injuries or other MSDs.

What are three different types of hazardous chemicals?

Three different types of hazardous chemicals are flammable materials, toxic substances, and corrosive agents. These categories represent a broad spectrum of chemical hazards, each posing unique risks depending on their properties and exposure level.

Flammable Materials

Flammable materials are substances that can easily ignite and burn rapidly. Their hazard lies in the potential for fire and explosions, causing significant property damage and potential harm to human health. The severity of the risk depends on factors such as the flash point (the lowest temperature at which a liquid can form an ignitable mixture in air), the flammability limits (the concentration range in air within which a substance will burn), and the presence of ignition sources. Proper storage, handling, and the use of appropriate safety measures are crucial to mitigate the risks associated with flammable materials.

- Examples: Gasoline, propane, ethanol, acetone.

- Hazards: Fire, explosion, burns.

- Safety Precautions: Proper storage in approved containers, away from ignition sources, use of appropriate personal protective equipment (PPE).

Toxic Substances

Toxic substances are chemicals that can cause harm through ingestion, inhalation, or absorption through the skin. Toxicity can range from mild irritation to severe organ damage or even death. The degree of toxicity depends on the specific chemical, the route of exposure, and the duration and level of exposure. Many toxic substances are acutely toxic, meaning they cause immediate harm, while others are chronically toxic, producing effects only after prolonged exposure. Accurate identification and handling of toxic substances are crucial, requiring thorough safety training and robust safety protocols.

- Examples: Cyanide, lead, mercury, pesticides.

- Hazards: Organ damage, poisoning, death.

- Safety Precautions: Proper ventilation, use of respiratory protection, avoidance of skin contact, careful handling, and disposal according to regulations.

Corrosive Agents

Corrosive agents are substances that can cause irreversible damage to living tissue or other materials through chemical reactions. This damage is often characterized by destruction of the surface, leading to burns, scarring, and other severe injuries. The corrosiveness of a substance is related to its pH; strongly acidic or alkaline substances are typically corrosive. The severity of damage depends on the concentration of the corrosive substance, the duration of exposure, and the material being exposed. Safe handling requires strict adherence to safety protocols, including protective clothing and equipment.

- Examples: Strong acids (sulfuric acid, hydrochloric acid), strong bases (sodium hydroxide, potassium hydroxide).

- Hazards: Burns, tissue damage, blindness (if in contact with eyes).

- Safety Precautions: Use of appropriate PPE, including gloves, eye protection, and protective clothing; careful handling and spill procedures; proper ventilation.

Reactive Chemicals

Reactive chemicals are substances that readily undergo chemical reactions, often violently or unpredictably. These reactions can generate heat, pressure, toxic gases, or other hazardous materials. The reactivity of a chemical is dependent on its chemical structure and its interaction with other substances or environmental conditions (e.g., temperature, pressure, presence of catalysts). Proper storage, handling and understanding the potential reactions are critical to avoid hazards.

- Examples: Alkali metals (sodium, potassium), peroxides, and many oxidizing agents.

- Hazards: Explosions, fires, release of toxic gases.

- Safety Precautions: Careful handling, isolation from incompatible materials, appropriate storage, and the use of specialized safety equipment.

Oxidizers

Oxidizers are chemicals that readily supply oxygen or other oxidizing substances and may cause or contribute to the combustion of other materials. They are often found in cleaning products, bleaches and industrial processes. Oxidizers can significantly increase the risk of fire and explosions when in contact with flammable materials. Understanding their properties and handling them safely is critical.

- Examples: Hydrogen peroxide, nitrates, chlorates, and perchlorates.

- Hazards: Increased fire risk, potential for explosions, and generation of toxic gases.

- Safety Precautions: Storage away from flammables, proper ventilation, use of personal protective equipment, and careful handling to avoid spills or contact with other materials.

What are some examples of chemical hazards in the workplace?

Chemical hazards in the workplace encompass a broad range of substances that can pose significant risks to worker health and safety. Examples are numerous and vary widely depending on the industry. In manufacturing, you might find corrosive chemicals like acids and bases used in cleaning or processing, which can cause burns and tissue damage upon contact. Similarly, flammable liquids such as solvents and fuels present a fire hazard and can lead to serious injuries or fatalities in case of spills or ignition. Toxic substances, like certain heavy metals or pesticides, can cause acute or chronic health problems through inhalation, ingestion, or skin absorption. The construction industry may expose workers to asbestos, a known carcinogen, or to cement dust, which can cause respiratory issues. Healthcare settings deal with various sterilants and disinfectants that, while necessary for infection control, can also be irritating or harmful if mishandled. Even seemingly harmless substances, if improperly stored or handled, can become hazardous. For example, cleaning agents can produce harmful fumes when mixed incorrectly or used in poorly ventilated areas. Identifying and properly managing these hazards through appropriate training, safety equipment, and controlled handling procedures is critical for workplace safety.

How can I identify a chemical hazard?

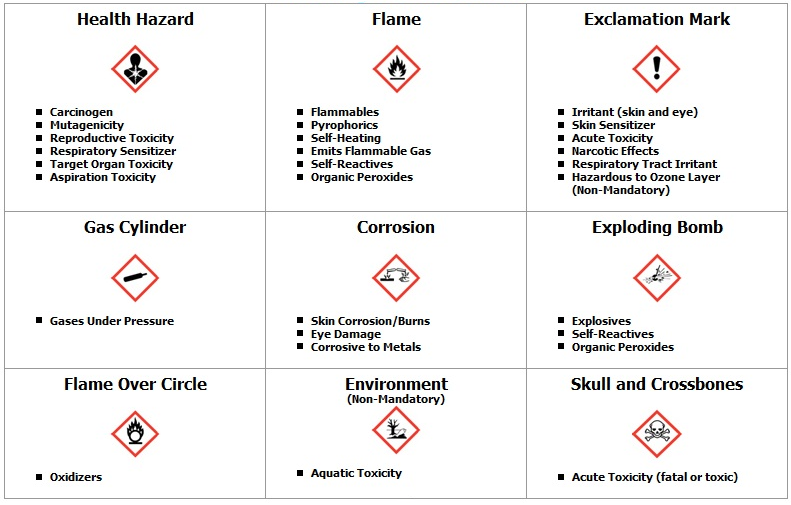

Identifying a chemical hazard requires a multi-pronged approach, combining careful observation, awareness of workplace processes, and access to relevant Safety Data Sheets (SDS). First, you need to understand the processes and materials used in your workspace. Are you handling any liquids, solids, or gases? If so, what are their properties? Look for labels on containers – these often indicate potential hazards using symbols (e.g., flammability, toxicity, corrosivity) and signal words (e.g., danger, warning). These labels point towards the need for further investigation through the SDS. The SDS, mandated by OSHA and other regulatory bodies, provides comprehensive information about a chemical's properties, hazards, and safe handling practices. This crucial document details potential health effects (acute and chronic), physical hazards (fire, explosion), and environmental hazards. Moreover, training and awareness are crucial. Workers need to be educated to recognize potential hazards and report any unsafe conditions. This includes understanding the signs and symptoms of chemical exposure, which can range from minor irritation to severe illness. Regular safety inspections and audits also play a vital role in identifying and addressing potential chemical hazards before they can cause harm.

What are the three main categories of chemical hazards based on their health effects?

While chemical hazards exhibit diverse properties and effects, they are often categorized based on their primary health impact. One common classification system divides them into: acute hazards, chronic hazards, and carcinogenic hazards. Acute hazards involve immediate or short-term effects after exposure. These might include skin irritation, eye irritation, respiratory problems, or even more severe consequences like poisoning or death, depending on the substance and the level of exposure. Symptoms typically manifest quickly after contact. Chronic hazards, on the other hand, involve long-term health effects resulting from repeated or prolonged exposure, often with a latent period before symptoms appear. These could include organ damage, reproductive problems, respiratory diseases (like asthma or lung cancer), or various other chronic illnesses. The effects often become apparent only after years of exposure. Carcinogenic hazards represent a specific subset of chronic hazards. These are substances known or suspected to cause cancer. The latency period before cancer development can be very long, making early detection and prevention extremely important. It's crucial to remember that some chemicals can cause multiple types of hazards; a single substance might pose both acute and chronic risks, including carcinogenic potential. Proper risk assessment and control measures must consider the entire spectrum of potential health effects.

What are some preventative measures for chemical hazards?

Preventing incidents involving chemical hazards relies on a comprehensive strategy encompassing various control measures. Engineering controls are fundamental, aiming to eliminate or reduce the hazard at its source. This includes implementing closed systems to minimize exposure, using ventilation systems to remove or dilute harmful fumes, and installing emergency showers and eyewash stations to provide immediate first aid in case of spills or splashes. Administrative controls focus on modifying work practices and procedures to reduce exposure. These include implementing standard operating procedures (SOPs) for handling chemicals, establishing clear labeling and storage protocols, and providing adequate training to workers on safe handling practices, emergency procedures, and the use of personal protective equipment (PPE). Personal protective equipment (PPE) provides the final layer of protection, acting as a barrier between the worker and the chemical hazard. This includes items such as gloves, goggles, respirators, aprons, and protective clothing, the choice of which depends on the specific hazard involved. Regular maintenance and inspection of PPE are vital to ensure its effectiveness. Furthermore, monitoring and surveillance programs should be in place to track worker exposure and identify any potential problems early on. These combined measures, implemented and consistently enforced, significantly reduce the risk of chemical hazards and promote a safer work environment.

Deja una respuesta